Goodyear Welted, Blake, Hand Welted, Norwegian, Bologna, Cemented & More

When it comes to high-quality footwear, the way a shoe is made is just as important as how it looks. Yet many people still confuse—or completely overlook—the types of shoe construction that affect not only the durability and comfort of a shoe, but also how it fits, breaks in, and ages over time.

So, to help you understand what really goes on beneath the surface, I’ve put together this full guide to the most commonly used shoe constructions in both ready-to-wear and bespoke shoemaking. Whether you’re just getting into quality shoes or refining your collection, this guide will help you make smarter choices and appreciate the craft even more.

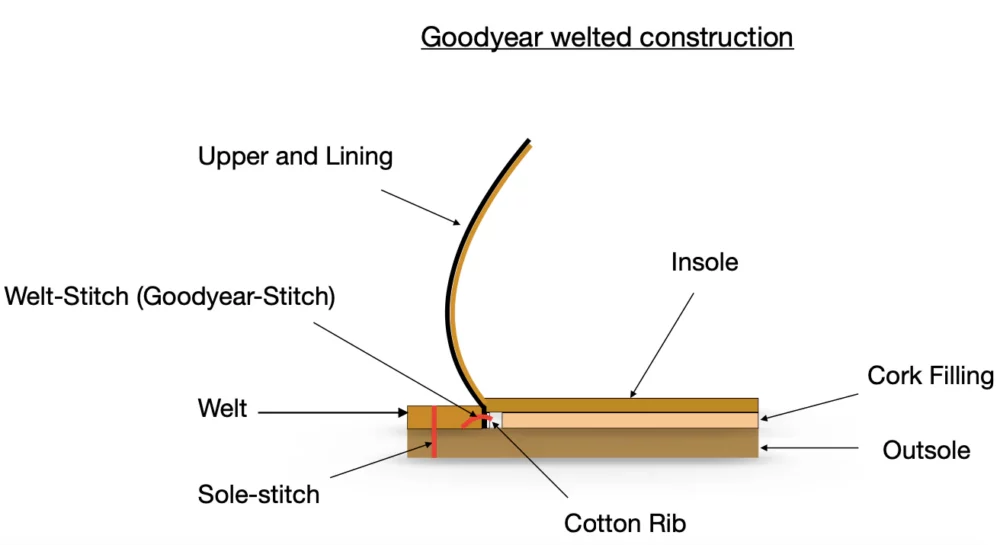

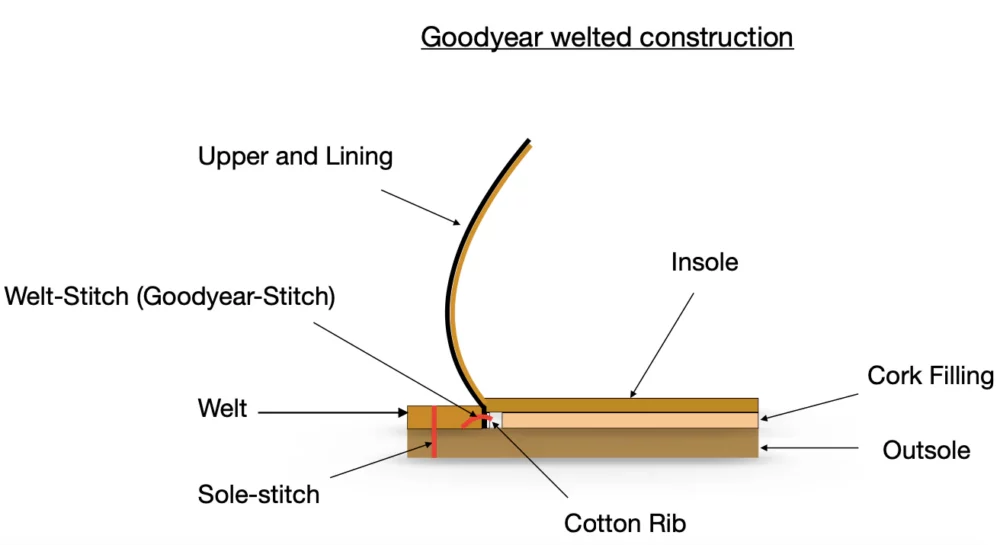

1. Goodyear Welted

Let’s start with the most respected shoe construction (on a production level) in classic men’s shoes: Goodyear welted.

This is the bread and butter of traditional English shoemaking and is regarded as the gold standard for durability, structure, and repairability. The welt—a strip of leather—is stitched to both the upper and a canvas rib attached to the insole. The outsole is then stitched to the welt, rather than directly to the upper. The benefit? You get a relatively waterproof build, a cork-filled footbed that molds to your foot over time, and a shoe that can be resoled over and over again—often lasting decades if well cared for.

While Goodyear welted shoes are often associated with English craftsmanship, the method was actually invented by Charles Goodyear Jr., son of the American inventor who developed vulcanized rubber. It is also becoming more common for a new brand to offer Goodyear Welted construction than it was, say, 20 years ago, where most new brands were Blake Stitched.

If you’re looking for a pair of shoes that can age beautifully and be serviced over time, Goodyear welted is the sweet spot of traditional construction.

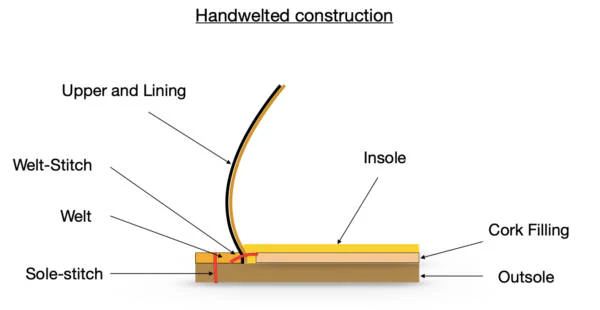

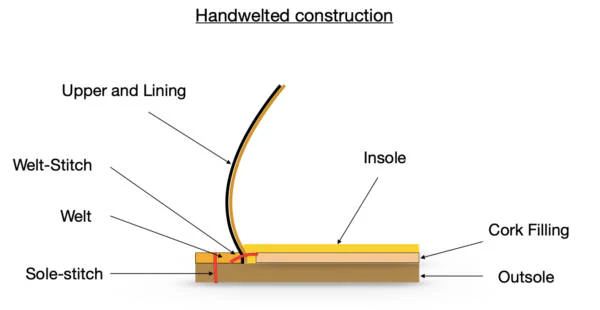

2. Hand Welted

Hand welted construction is, in many ways, the older and more labor-intensive brother of Goodyear welted.

It follows a similar theory—stitching the welt to the upper and insole—but it’s all done by hand, without the use of a canvas rib. Instead, the shoemaker manually carves a feather from the insole, which the welt is stitched into directly. This allows for a thinner, more refined sole while still retaining excellent durability and repairability.

The use of the hand welted construction is most often found in bespoke or high-end shoes, and while it takes much longer to produce, the end result is usually cleaner, and often more elegant in execution. If you value artisanal craftsmanship and don’t mind paying for it, hand welted shoes are about as good as it gets.

Historically speaking, getting hand welted footwear was going to cost you extra money, but with the rise of Asian manufacturing, you are seeing hand welted options sub $500.

Of all the various types of shoe construction, Hand Welted is often regarded as the most prestigious.

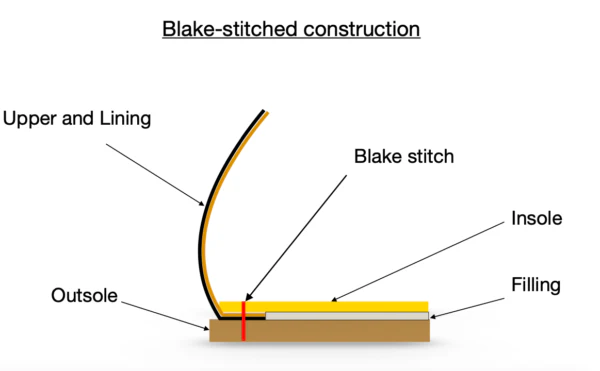

3. Blake Construction

Blake construction is widely used in Italian shoemaking and is known for its sleek, lightweight feel. In this method, the outsole is stitched directly to the insole and upper. This creates a very flexible, close-cut profile—great for slim, elegant shoes.

The drawback? It’s not as waterproof or as easy to resole as Goodyear or hand welted shoes. Also, since the stitching goes through the entire shoe, it can be more vulnerable to moisture seeping in. You’ll also find fewer cobblers equipped to resole them, especially if they don’t have a Blake machine.

Still, a well-made Blake shoe has its place, especially for warm weather or more refined silhouettes where flexibility and lightness are priorities.

4. Blake Rapid Construction

Blake Rapid is essentially Blake with a twist. Instead of stitching the outsole directly to the insole, there’s a midsole involved, which the outsole is then stitched to. This adds an extra layer of durability, slightly more cushion, and allows for easier resoling compared to standard Blake.

Some say a well-made Blake Rapid shoe can rival a Goodyear welted one. And while that might be true on paper, personally, I still lean toward Goodyear construction—it’s what I’ve learned to make and appreciate the most. But that doesn’t mean Blake Rapid is inferior; it’s just different.

Of the various types of shoe construction, the Blake Rapid is probably among the least used. Most brands either go Blake or Goodyear.

5. Norwegian (Norvegese) Construction

Despite the name, Norwegian construction is another technique that’s often seen in Italian shoemaking. Originally developed for creating waterproof footwear, it features a distinctive wraparound welt that’s visible from the outside.

In its true form, the welt sits fully on the outside of the shoe, stitched flush with both the sole and the upper. This creates a rugged, weather-resistant build ideal for outdoor use. But today, Norwegian stitching is also used decoratively to give a shoe a bold, chunky look—even if it doesn’t offer true waterproofing.

If you want a shoe that looks unique and stands up to the elements, this is a solid choice. But keep in mind: this construction tends to be heavier, stiffer, and costly.

6. Bologna (Sacchetto) Construction

Bologna construction, sometimes referred to as ‘Sacchetto (bag),’ is all about comfort. Commonly found in Italian loafers and lightweight dress shoes, this method involves wrapping the lining into a sock-like shape and stitching it to the upper, eliminating the need for a traditional insole.

The result is a super flexible, slipper-like feel. It’s not as durable or supportive as welted construction, but for soft, elegant footwear—especially for indoor or light use—it’s incredibly comfortable.

Just don’t expect it to last you 15 years. This is luxury in the moment, not longevity.

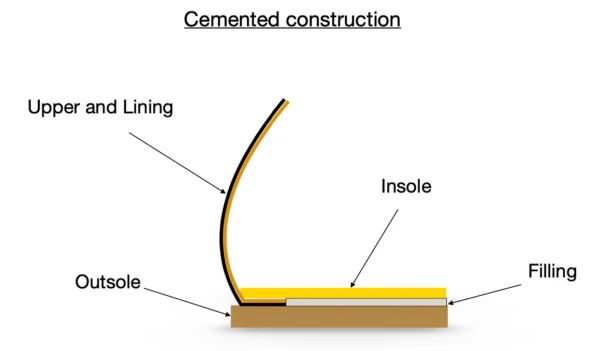

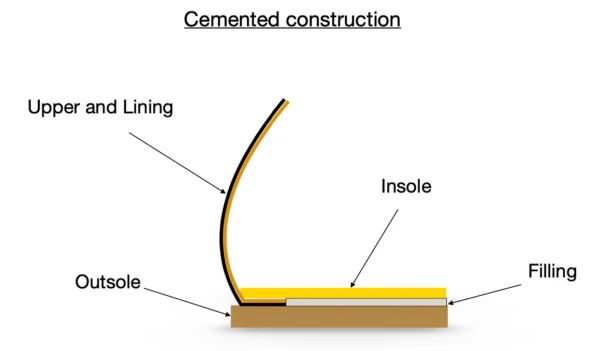

7. Cemented Construction

Cemented (aka glued) construction is the most cost-effective method in the industry. The outsole is simply glued to the upper, which makes it fast, cheap, and lightweight—but also disposable.

This is the construction you’ll find in most fast-fashion shoes. Once the sole wears down or separates, it’s game over. There’s no real way to repair it, and the upper tends to wear out just as fast.

I’d only recommend cemented construction for shoes you don’t plan to wear often, or when you need something quick and affordable. It has its place—but it’s not in your rotation of long-term staples.

Of all of the types of shoe constructions, the cemented method is the most prevalent as it is the cheapest.

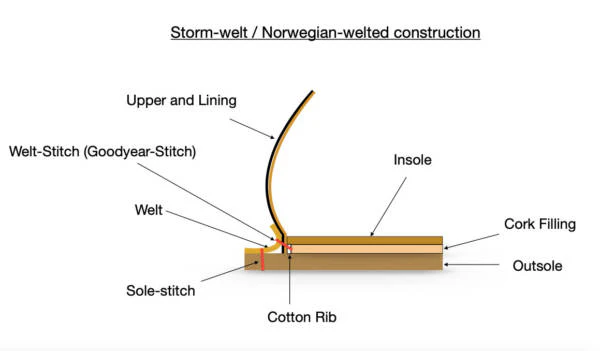

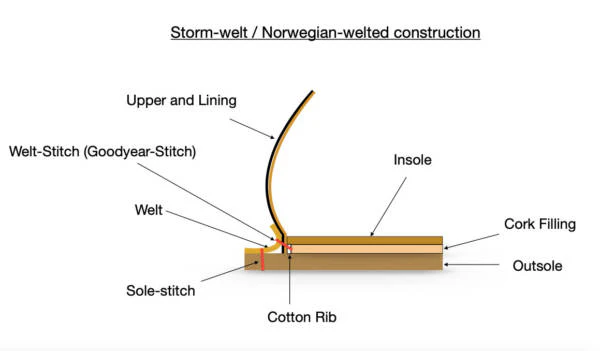

8. Storm Welt Construction

Storm welt is a variation of Goodyear construction that adds a raised lip or flap of leather running along the perimeter of the shoe, where the upper meets the sole. It’s designed to provide extra water resistance and protection from the elements.

You’ll most often see this used in country boots or heavy-duty footwear—basically anything that needs to hold up in rougher weather. The look is chunkier and more rugged, which some people love (and others avoid).

Functionally, it’s one of the best options for wet climates or winter use.

9. Moccasin Construction

Often found in boat shoes, driving loafers, and casual slip-ons, moccasin construction wraps the upper leather underneath the foot and stitches it along the top of the vamp. This creates an extremely soft, unstructured, and flexible shoe.

It’s great for comfort and laid-back style, but lacks the support and longevity of structured builds. Best saved for summer wear or light, casual use.

10. Strobel Construction

Common in sneakers and modern casual footwear, Strobel construction involves stitching a textile insole directly to the upper, then gluing the outsole on afterward. It’s efficient and lightweight but designed purely for function—there’s nothing traditional or long-lasting about it.

Still, it allows sneakers to stay flexible and breathable, which is why it’s become the industry standard for athletic and performance shoes.

Conclusion: Which Shoe Construction Is Right for You?

Choosing the right shoe isn’t just about style—it’s about how the shoe is built to support you over time. Whether you prioritize comfort, longevity, weather protection, or elegance, there’s a construction method that fits your needs.

If you’re looking for versatility and long-term value, Goodyear welted is hard to beat. Want something soft and elegant? Bologna is worth a try. Need a rugged winter boot? Storm Welt or Norwegian has you covered.

The more you understand these types of shoe construction, the more confident you’ll feel building a wardrobe that’s both stylish and built to last.

—Justin FitzPatrick, The Shoe Snob